|

GC “ASOMI” produces strut mounts, struts, shock absorbers, coil springs, assembled units, the stabilizer of cross stability and other suspension components for cars VAZ, Renault Logan, Chevrolet Niva, Gazelle and other car brads. Map of dealers help you quickly find the official representative of ASOMITM in your city. If you want to become a supplier of "ACOMI" (Togliatti), complete the application form of supplier. We will consider your suggestions! If you want to become an official dealer of TM ACOMI, complete the application form of the dealer or contact us by phone!

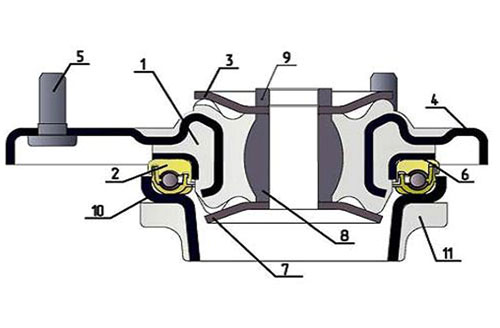

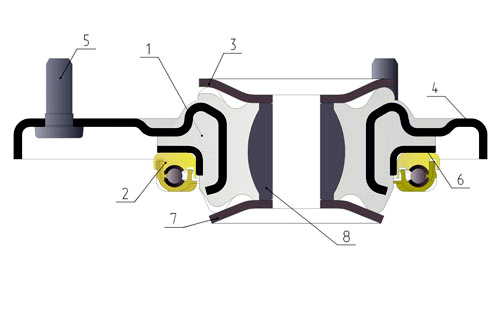

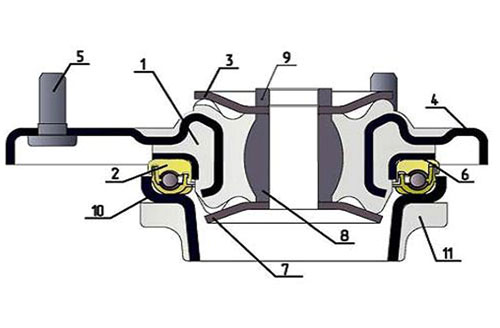

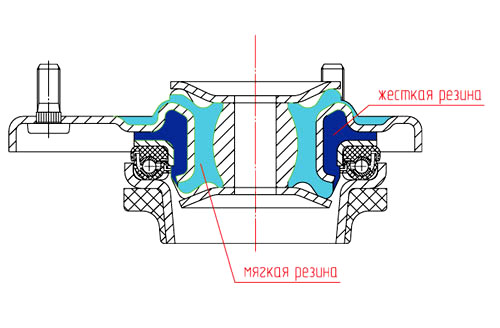

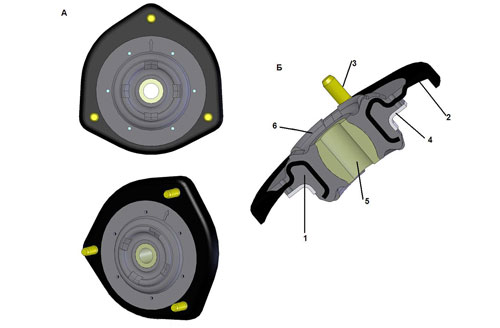

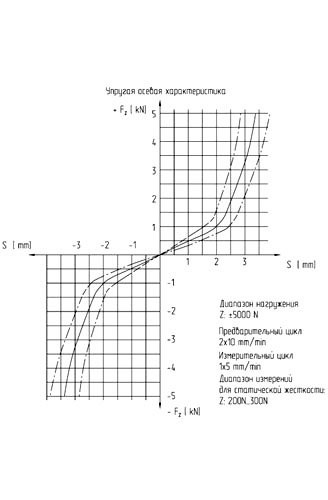

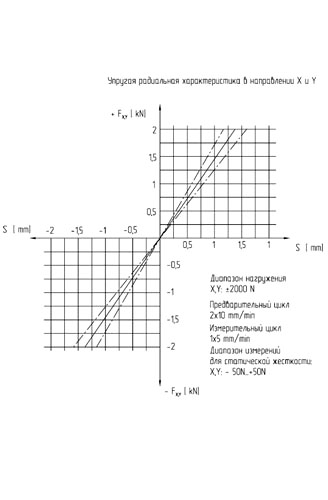

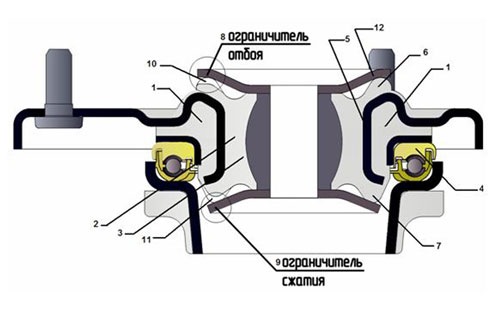

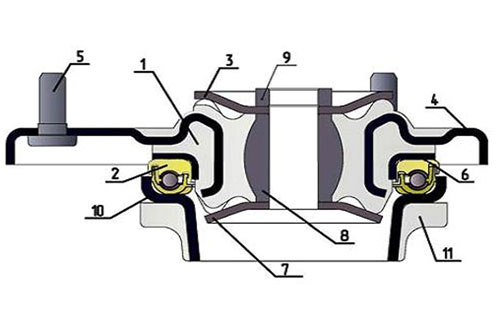

Technical design and supports the benefits of TM ASOMI car Lada Kalina and Lada PrioraTechnical design and supports the benefits of TM ASOMI car Lada Kalina and Lada PrioraThe upper support pillars are rubber steel node that receives the bulk of all the loads transmitted to the vehicle body by the suspension of the guide device, the damping force racks and elastic forces of the spring and buffer compression stroke. Props also play a crucial role in ensuring "primary" sound insulation and vibration of the vehicle.  Specialists of "ASOMI", realizing the importance of these components in the suspension, created a fundamentally new design of the top support strut front suspension for cars Lada Kalina and Lada Priora (Patent number 90381). Applicability: LADA KALINA (1117, 1118 and 1119 events.) LADA PRIORA (2170, 2171, 2172 and mod.). The design supports TM ASOMI car Lada Kalina and Lada Priora  Prop TM ASOMI (Fig. 1 and Fig. 2) consists of a support A119.2902.821 (1), the outer housing (4) with fastening screws (5), the inner sleeve (8) and bearing support (6) connected to the housing start vulcanised rubber. Bearing thrust type (2) is a sealed design with a durable lubricant. He has landed on the bearing support (6). Stroke limiter rebound (3) and compression (7) intended to limit the movement of the inner sleeve (8), arising in the course of the wheel, as well as contribute to the absorption of energy in the spring decompresses the end of the stroke rebound and compression when hit by a car on the bumps in the road that provides a durable resource TM supports an ASOMI. We describe the main differences and advantages of supporting TM ASOMI. 1. Offset of fixing bolts support TM ASOMI Prop TM ace formed with an offset relative to the axis of the fastening bolts of the central axis of the sleeve (rack rod axis). This revision allowed to use support for different versions of the suspension of cars Lada Kalina and Lada Priora, as well as increase its service life several times. The only difference supports TM ASOMI car Lada Kalina and Lada Priora - it is their equipment. Reliance TM ASOMI car Lada Priora consists of 4 main elements (Fig. 1): - Actual support A119.2902.821 (1) - The rolling bearing (2) - Stroke limiter rebound (3) - The compression stroke limiter (7).  Fig. 1. The device of the top support strut telescopic front suspension for Lada cars Priora A170.2902.821. Cut 1 - Reliance A119.2902.821. 2 - Bearing. 3 - Stroke limiter switch. 4 - The outer casing. 5 - Mounting bolts. 6 - Bearing support. 7 - Limiter the compression stroke. 8 - The inner sleeve. The package supports TM ASOMI car Lada Kalina (Fig. 2) in addition to the support A119.2902.821 (1), rolling bearing (2), travel stop hanging up (3) of the compression stroke limiter (7) further includes: a remote bush (9) cup spring (10), an insulating pad (11), designed for installation support.  Fig. 2. The device of the top support strut telescopic front suspension for cars Lada Kalina. Cut 1 - Reliance A119.2902.821. 2 - Bearing. 3 - Stroke limiter switch. 4 - The outer casing. 5 - Mounting bolts. 6 - Bearing support. 7 - Limiter the compression stroke. 8 - The inner sleeve. 9 - Bush remote. 10 - Cup spring. 11 - Laying insulation. 2. Increased body rigidity support TM ace Specialists of "ASOMI" made changes and improved the chassis serial support having insufficient stiffness in the axial direction. Maximum hard body supports TM ASOMI car Lada Kalina and Lada Priora is unique! Increased body rigidity supports TM ASOMI allowed: - To completely eliminate the deformation of the body and squeezing Cup car, - To improve the stability and controllability of the car, - At times to increase the resource supports. 3. Two damping work areas support TM ASOMI An important feature supports TM ace car Lada Kalina and Lada Priora is the original design of the rubber support member, start vulcanised to the inner and the outer surface of the housing support and performed on different parts of a rubber mixture with different Shore A hardness (Fig. 3).  Fig. 3. Damping work areas supports TM ASOMI. The first portion - is the area of the bearing support, on which the spring force is transmitted, it has a hard rubber. The second portion - a zone vulcanization inner sleeve, which transmits the force damper has a soft rubber. This technical solution supports TM ASOMI car Lada Kalina and Lada Priora car improves vibration isolation, reduces the overall noise level to 4 dB., Provides a smooth damping effect (absorption) vibrations upper support strut front suspension of the car (as opposed to the production of poles, which have insufficient vibration damping properties). This limits the movement of the rack rod and formed a progressive characteristic of the upper support, which increases power consumption. Furthermore, due to the annular support ribs TM ASOMI and recessed support portion (6), increases reliability of the connection of the elastic insert body, which correspondingly increases the life of the bearing TM ASOMI several times (Fig. 4).  Fig. 4. The device of the top support strut front suspension TM ASOMI car Lada Kalina and Lada Priora. A) General view. B) incision. 1 - Prop. 2 - The outer casing. 3 - Fixing screws. 4 - Bearing support. 5 - The inner sleeve. 6 - The rubber element. 5. The ideal ratio of axial and radial stiffness (400/1500 N / mm) supports TM ASOMI Supports TM ASOMI car Lada Kalina and Lada Priora has the perfect ratio of axial and radial characteristics of 1500 N / mm and 400 N / mm, respectively (Fig. 5 and Fig. 6). Because of this reliance TM ASOMI has a very long service life and optimal performance for noise, vibration and handling control. In the development of support specialists of "ASOMI" follow the recommendations of WOCO, a world leader in the design and manufacture of rubber products for automobiles.  Fig. 5. The elastic characteristic of the axial bearings TM ASOMI car Lada Kalina and Lada Priora.  Fig. 6. The elastic characteristic of the radial bearings TM ASOMI car Lada Kalina and Lada Priora. 6. The original design of improved travel stops rebound and compression stroke Specialists of "ASOMI" developed and applied in supports TM ASOMI car Lada Kalina and Lada Priora improved travel stops rebound and compression with optimized design. Belleville travel stops are provided with rebound and compression of the flat annular peripheral portion, which abuts against the upper annular elastic member of the elastic support insert (Fig. 7). The technical result of the use of this design constraints rebound and compression stroke is to improve vibration-damping properties of the support TM ASOMI, increasing its working life and increase the ride vehicle.  Fig. 7. Cut the support TM ASOMI car Lada Kalina and Lada Priora.  The reason is, while driving on Russian roads, when driving over bumps, the car wheel oscillates, and the low-frequency oscillations of the spring strut front suspension for the most part are damped by (absorbed by) an elastic seal disposed between the cup and the spring. A smaller portion of low frequency vibrations through the bearing (4), the bearing sleeve of the upper support part (1) of the elastic insert (3) of the upper bearing and the housing (5) is transmitted to the upper support body and the high-frequency oscillations are damped by the rack rod (absorbed) part ( 2) an elastic insert (3) of the upper support. In uniform motion of a vehicle on a level road through the suspension for body transmitted vibration caused by fine irregularities and hard rolling tire rack rod oscillates so that a portion (2) of the elastic insert (3) of the upper support TM ASOMI Shear its layers, while achieving maximum efficiency of vibration absorption and comfort drive. When the force transmitted to the upper support TM ASOMI through the rod increases, and this is at running the wheels on large bumps or contact with the wheel in a hole in the work come Belleville stops strokes compression (9) and rebound (8). Due to the presence on the top (6) and lower (7) of the elastic annular elastic member insert (3) of projections (10) and (11) respectively in contact with the periphery of the annular planar portion (12) of the poppet rebound stroke limiter (8) and a poppet stop compression stroke (9) is provided smooth damping effect (absorbance) vibration upper support since data projections (10) and (11) perform the function of the soft-start portion of the material that should work in compression at a given time. This limits the movement of the rack rod and formed a progressive characteristic of the top support TM ASOMI, which increases its power consumption at smaller overall dimensions. 7. Custer. The increase to + 0,5 ° on cars Lada Priora After installation supports TM ASOMI cars Lada Priora value of caster (the angle of inclination of the axis of rotation of the longitudinal wheel) is + 0,5 °. The increase in caster angle to improve camber change when the wheels turn and a positive effect on the car's handling, as it increases the stabilization of the shoulder. Slightly increased + 0,5 ° caster improves informative steering and improves self-resetting steering. In other words, the car Lada Priora with supports TM ASOMI better managed, especially at high speed. Thus, the support of TM ASOMI car Lada Kalina and Lada Priora has the following advantages: - Versatile design supports TM ASOMI, made with the offset of the axis relative to the axis of fixing bolts rod racks, suitable for installation in a vehicle suspension Lada Kalina and Lada Priora; - An increase in body rigidity supports TM ASOMI eliminates deformation of the body and squeezing Cup car; - 2 work areas damping supports TM ASOMI improved vibration isolation of the car and reduce the overall noise level to 4 dB .; - The original configuration of the rubber-metal element supports TM ASOMI enables high smoothness and absorption capacity high dynamic loads; - An increased service life; - Optimized design constraints stroke rebound and compression stroke supports TM ASOMI improved vibration damping properties of the support, it increases the life of the work and increases the smoothness of the car; - Increase caster supports TM ASOMI up + 0,5 ° for cars Lada Priora increases informative steering and improves self-resetting steering.

ASOMI, Ltd.

49 Topolinaya st, Office 10 Togliatti, Russia 445030 Tel.: +7 (8482) 73-41-11, +7 (8482) 20-88-50

“ASOMI” Togliatti – Production of strut mounts, struts, shock absorbers, coil springs, bearings and other suspension components for LADA, Renault Logan, Ford Focus, Chevrolet Niva, Gazelle and other car brands. Auto parts and tuning for LADA automobiles.

|